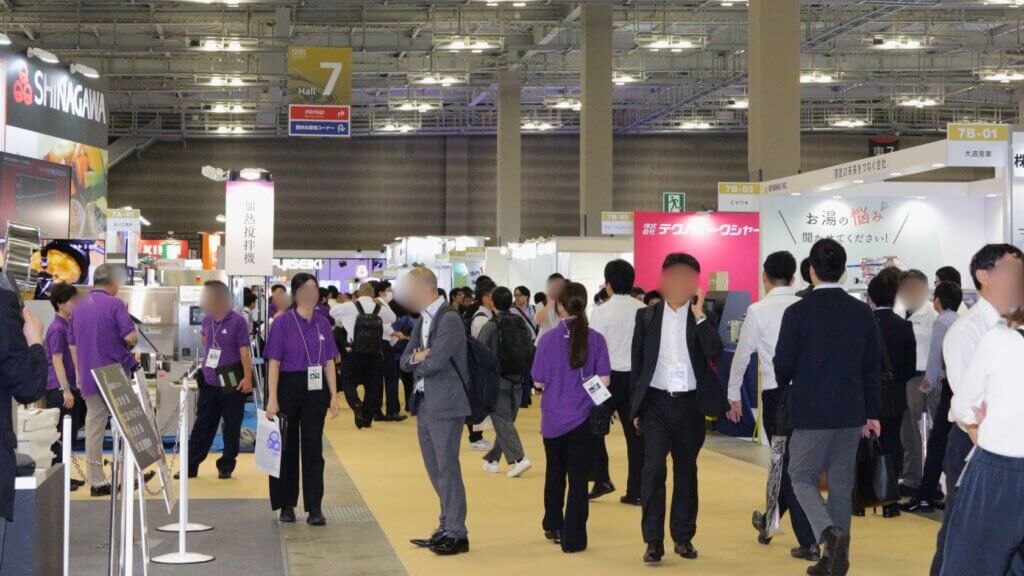

FOOMA JAPAN 2025 Report — A Vibrant Show Floor and Bold Moves by Long-Established Manufacturers and Startups

FOOMA JAPAN 2025 — the World’s Leading Food Processing Expo — has opened, inviting visitors to “Touch FOOMA, Taste the Future.” The show spans 21 fields across food manufacturing, with nearly 1,000 exhibitors presenting over 5,000 state-of-the-art solutions under one roof. We visited the venue to report on what’s happening at the forefront of the food manufacturing industry.

Event Overview

Name: FOOMA JAPAN 2025

Objective: To foster the exchange and dissemination of technologies and information on food machinery, equipment and related devices, and to contribute to the further development of the food industry. With growing interest in food safety and security, the show presents a richer future enabled by advanced machinery, products and services.

Dates: June 10–13, 2025

Hours: 10:00 a.m.–5:00 p.m.

Venue: Tokyo Big Sight, East Halls 1–8

Theme: Touch FOOMA, Taste the Future

Organizer: The Japan Food Machinery Manufacturers’ Association.

Official Website https://www.foomajapan.jp/int/?stt_lang=en

All Technologies Under One Roof: “Japan’s Largest Scale”

As billed by the organizer, this exhibition brings together every technology related to food manufacturing without focusing on a single item category (such as confectionery or meat). FOOMA JAPAN’s defining feature is that it aggregates solutions for all types of ingredients and processes in one place.

A wide range of special programs were available on site:

- Startup Zone: A showcase of innovative startups

- FOOMA Awards: Honors cutting-edge food machinery and equipment

- Academic Plaza: Exhibits the latest research from industry–academia–government collaboration

- FOOD TOWN: Consultation services for food manufacturing automation

- Management Support & Export Consultation Corner: Advisory desks for diverse business needs

Beyond these, daily seminars and symposiums were held. Visitor My Page, the official app, free Wi-Fi, the FOOMA Tokyo Bar lounge, and even sales of regional ekiben rounded out services designed to meet diverse visitor needs.

Heritage and Innovation: Long-Established Leaders Taking on New Challenges

Longstanding companies that have supported Japan’s food manufacturing industry for decades are presenting new proposals that leverage their technology and experience. This time we focused on two exhibitors: MULTIVAC JAPAN INC., known for processing and packaging, and Yushin Company, which applies robotic technology to food logistics.

MULTIVAC JAPAN INC.: Over 50 Years in Processing and Packaging

As the Japanese subsidiary of Germany’s MULTIVAC, MULTIVAC JAPAN INC. has a history of more than 50 years. While widely known for packaging machines, the company now handles a broad lineup of equipment that streamlines upstream preparation and processing, including meat-processing machines and mixers.

The company has exhibited at FOOMA for over two decades, in fact for more than 25 consecutive editions. It is focusing on the pressing issue of labor shortages in food factories, supporting manufacturers through proposals such as packaging formats that extend shelf life, optimization tailored to each customer’s product and film, and technologies that enable mass production. These contribute to both operational efficiency and sustainability, with particular expertise in minimizing waste when processing animal products such as meat.

The booth drew many food manufacturers and distribution professionals seeking solutions for time reduction and improved yield. Mini croissants were sampled at the stand—crisp on the outside with beautiful butter layers. The consistent quality achieved by computer control was a clear example of technology-enabled quality management.

With the future challenge of a shrinking population in mind, the company aims to combine multiple technologies to ensure the stable supply of safe, delicious food. As a behind-the-scenes partner to food plants, it plays an essential role in supporting Japan’s food safety and security.

Yushin Company: Our “Progress” Leads to Customer “Safety” and “Progress”

Yushin Company, based in Kyoto and a top domestic player in take-out robots for plastic injection molding, applies its industrial robotics know-how to food logistics. At FOOMA the company showcased a palletizer designed for shipping operations.

This year marks Yushin’s third appearance at FOOMA. In response to rising demand from the food industry, the company chose to exhibit at Japan’s largest show to strengthen its front-line presence. Its approach is closely aligned with FOOMA’s “next generation” theme: in shipping sites facing labor shortages, rising labor costs, and occupational safety risks, the introduction of robots for repetitive tasks is becoming inevitable. Yushin frames this as a forward-looking way of working and a smarter use of resources, actively promoting robotic adoption.

The team expected many visitors dealing with shipping-related challenges, including the “2024 logistics problem.” For companies struggling to move forward, FOOMA is an opportunity to see the equipment in action. Flexible customization to fit each customer’s products is presented as a key strength.

A representative summed up the company’s stance: the president encourages teams to sell all products—beyond palletizing robots—under the banner of progress and safety, with developers taking the lead. The progress Yushin creates becomes safety for customers, and in turn enables progress in factory efficiency. The ideal is to keep advancing together under this shared theme.

Suzumo Machinery Co., Ltd. (SUZUMO): Sushi robots and rice-portioning robots

Founded in 1955 and incorporated in 1961, Suzumo Machinery is the industry’s leading manufacturer that developed the world’s first sushi robot in 1981. At the booth, the company showcased its lineup of sushi robots alongside rice-portioning robots.

Hattori Kogyo Co., Ltd.: Robot rotary kettle with chef-level technique

Hattori Kogyo was founded in 1885, giving the company a 140-year history. The booth featured demonstrations of a robot rotary kettle that reproduces the techniques of experienced chefs, with tastings offered to visitors.

Startup Zone: A Place for Discovery and Hands-on Experiences

Even booths with only counter-sized spaces saw a constant flow of visitors. An adjacent stage hosted daily pitch sessions, where large audiences listened closely to each company’s presentation.

A visitor-voted “Startup Grand Prix 2025” also took place, making this an area where you can truly feel how innovative technologies are expanding the possibilities of food. The atmosphere was charged with people looking to meet future business partners.

Friend Microbe: Breaking Down Oils with Microbes for a Sustainable Future

Friend Microbe, a Nagoya University–origin startup founded in 2017, has developed an innovative technology that efficiently decomposes fats and oils in wastewater using microorganisms. At the booth, a demo video showed oil-laden water reduced to nearly clear in just eight hours through microbial action.

The technology reduces waste, lowers costs, and cuts CO2 emissions, contributing to a more sustainable society. In its second appearance at the show, the team is actively seeking partners to help scale the solution. The booth has become a valuable forum for hearing real-world pain points about oil from food manufacturers and equipment makers.

Visitors included many from the food industry, including machinery suppliers to food factories. This direct feedback from the field is helping the team sharpen its product–market fit.

Kansei AI: Analyzing Human “Kansei” with AI, Now Applied to Mouthfeel

Kansei AI is a 2018 venture jointly established by Keio Corporation and the University of Electro-Communications. The company offers unique services that make human “kansei” (sensory impressions) measurable with AI.

Two core services were presented. First, “Analytics,” which predicts how general consumers will feel about elements like packaging design (for example, a sense of friendliness). Second, a service that quantifies tactile qualities—such as the feel of fabrics or leather—to support manufacturers’ prototyping.

The team’s current focus at FOOMA JAPAN is applying this second, touch-analysis technology to food. By quantifying mouthfeel, they aim to enable product development that goes beyond ease of eating to deliver enjoyment, delight, and other aspects of well-being.

Because “kansei” is a niche domain, the primary goal is to steadily build recognition by exhibiting at a specialized show like FOOMA. The company is prioritizing the food sector and exploring collaborations with various partners.

Their long-term vision is ambitious: today they analyze textures; tomorrow they want to suggest concrete formulations to achieve target textures—advancing toward a materials informatics–like capability that accelerates R&D and unlocks new possibilities for food through AI and kansei science.

The photo of the startup pitch presentation is published with the company’s permission.

ARK: Building “Seas” on Land with the Next Generation of Aquaculture

ARK is a startup developing and selling compact, land-based aquaculture systems so that anyone can start aquaculture anywhere. Their solution combines an in-house–designed and manufactured tank platform (hardware) with a smartphone app for water-quality management (software). The company has already shipped 41 units across 17 prefectures in Japan.

Users range widely—from firms launching new businesses to operators at roadside stations and hotels integrating aquaculture into existing services, as well as university research groups. ARK began exhibiting at FOOMA JAPAN in 2023, using the show to generate sales leads and debut the product. The Startup Zone has been a major boost, and the team reports strong responses—orders and referrals in Japan and inquiries from abroad centered on their UK base.

Founded in 2020 by members with IT consulting experience in the fisheries sector, ARK concluded that solving on-site problems required not only software but also hardware. The system makes extensive use of IoT, allowing users to check sensor-derived water-quality data from anywhere via smartphone.

While equipment sales are currently central, the next phase is to sell fish raised with ARK’s system. The ultimate goal is to create countless “little seas” on land—an “eighth sea” that gives the ocean time to recover by shifting some production onto land.

FOOMA JAPAN: Where Heritage Manufacturers and Startups Thrive Together

A major highlight of FOOMA JAPAN is seeing long-established companies apply their accumulated technologies to solve today’s challenges. Across the venue, many firms with deep histories and technical strength were tackling contemporary issues head-on.

The sector moves forward when the know-how of heritage leaders meshes with the boundary-pushing energy of startups. That synergy points to a richer, more sustainable future for food—and it felt tangible on the show floor.

Related Articles : Startup & Tech Event

-

On-the-ground report: A Megijima-based reporter guides you through Setouchi Triennale 2025 — from standout artworks and recommended spots to how islanders live with the festival

-

BitSummit The 13th in Kyoto — Business Day Highlights: Standout Indie Games from Japan and Overseas (Even If You Couldn’t Attend)